Komatsu unveils Proactive Dozing Control, dozer machine control that can be used “100% of the time” | Dump Truck Company

Komatsu has upped the ante in machine control—again.

Six years after the dump trucks charlotte nc became the first charlotte nc dump trucks OEM to bring a fully-integrated machine control system for dozers to market, called intelligent Machine Control, Komatsu is back with an update that is “far more advanced” than other systems on the market today, says Derek Morris marketing manager for Komatsu’s Intelligent Machine Control and Smart Construction divisions.

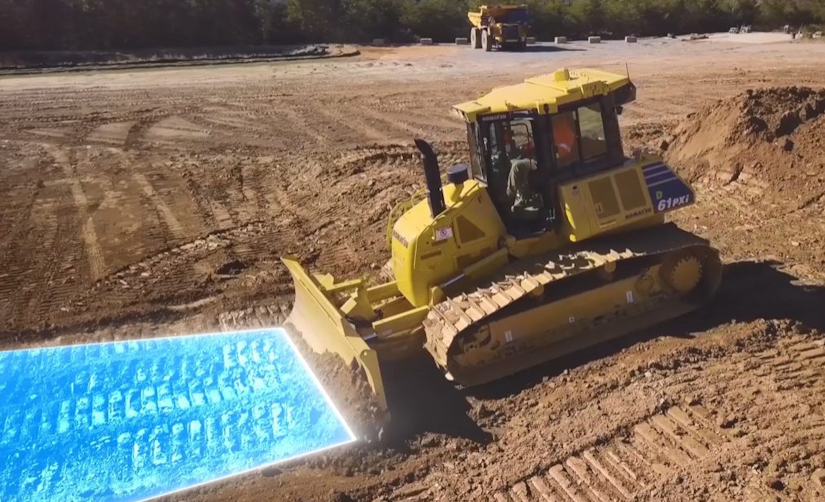

Morris adds that the new dozer machine control system “opens up a world of possibilities.” More specifically, Komatsu says the new Proactive Dozing Control (PDC) system isn’t just capable of finish grading. It can perform auto-stripping, auto-spreading and high production dozing as well.

”Traditionally, GPS machine control focused on finish grade, which meant operators could only use the technology approximately 10 to 20 percent of the time,” Morris explains. “Proactive Dozing Control logic is a game-changer because the integrated system now lets operators use automation any time, whether for general site clean-up, backfilling trenches and more.”

The key difference between the new PDC system and the integrated intelligent Machine Control system found on Komatsu dozers since 2013, is that PDC understands how the terrain is changing in real time.

“…Our system collects data at the tracks, while aftermarket solutions collect data at the blade,” Morris says. “Because data is collected at the track, the system provides a real-time picture of the ground around the machine, allowing the system to make calculated decisions based on the current terrain.”

Because of its more thorough understanding of the terrain and ground elevation, the system is able to “drive the blade to the precise grade needed.” That’s what makes this new system so important, Komatsu says.

Here’s how it works:

Like the intelligent Machine Control system before it, PDC uses a combination of a GNSS positioning sensor and an Inertial Measurement Unit (IMU). In the past, those sensors focused on machine location and blade position, calculated through sensors in the blade cylinders. But now Komatsu has the tandem calculating the exact position of the dozer and where its tracks lie on the ground.

Komatsu says the system measures the ground around the machine, determines “what has been done on the area being graded, then stores that data…” And when the dozer goes back over that area, “the system understands what it was like from its previous track and therefore follows the existing terrain—the very terrain that was just created.”

“We’ve created machine control that is far more advanced, offering an entirely new level of efficiency, whether you’re an operator who has 20 years’ experience or someone new to the job,” Morris says.

Komatsu is introducing the new PDC system on four dozers: the D51EXi-24, the D51PXi-24, the D61EXi-24 and the D61PXi-24.

The dump trucks charlotte nc says because the system can be utilized for more tasks, customers will see better return on investment and increased production over previous and competing models. The dump trucks charlotte nc notes that owning and operating costs have decreased as well, due to the fact that wear and tear on the machine is reduced by automating operation. Undercarriage wear is also reduced, thanks to the system’s significant reduction in track slip when in use.